Bhawani Engineering, led by marine engineers, specializes in manufacturing marine deck equipment such as rescue boat davits, winches, tow hooks, capstans, etc. Bhawani is one of the few companies in India that manufacture davits, cranes essential for launching lifeboats/rescue boats during emergencies. To ensure the reliability of this critical life-saving equipment, Bhawani sends technicians and engineers to service and maintain davits for various shipowners. They follow stringent international safety standards set by SOLAS (Safety of Life at Sea), which mandates meticulous inspections and detailed record-keeping. As their operations grew, Bhawani recognized the need for a robust service management software to streamline their processes and ensure compliance with international regulations.

Challenge: Manual Inefficiencies

Bhawani Engineering faced several significant challenges that created the need for a service management software.

Addressing these challenges was crucial for Bhawani to maintain their reputation and ensure the safety of their products:

-

Tracking Davit Ownership: In the past 30 years, Bhawani sold davits to many shipping companies, and many such companies changed ownership. With around 400 davits in service, it became increasingly difficult to track their locations and compliance statuses.

-

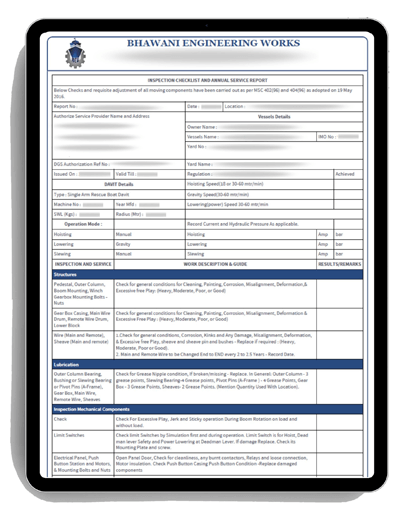

Manual Processes: The company relied on handwritten checklists and records, making it difficult to send/receive checklists, consolidate reports, and verify records. This manual approach was not only time-consuming but also prone to errors, leading to inefficiencies and potential compliance issues.

-

Inefficient Communication: Bhawani utilized third-party service providers for many inspections and often faced logistical hurdles in dispatching checklists to them and getting back reports in a timely manner.

Solution: Implementing Automation

Recognizing the need for a centralized service management system, Bhawani Engineering turned to Optimum Info. Initially hesitant due to Optimum’s lack of experience in the marine industry, Bhawani decided to proceed with a pilot project, which proved to be highly successful.

The implementation process was methodical and well-structured. Bhawani first provided Optimum with an overview of their company, regulatory requirements, and the existing checklist system. Next, Bhawani’s handwritten records were converted into a structured database, categorizing different davit models and assigning each a serial number per Optimum’s recommendation.

Optimum then designed a workflow outlining the entire service process, from work order creation to certification issuance. The system was customized to align with Bhawani’s unique terminology and workflow requirements.

Training and adoption were swift, with Bhawani’s employees adapting within a week and other approved service stations becoming proficient after a one-hour training session, achieving full competency in just two weeks.

Mohit M., Owner Representative of Bhawani Engineering, praised the smooth transition, stating,

Implementation was very easy for us. We simply explained the flow chart to our account manager at Optimum, and she took care of everything. She worked with us to use our marine terminology with the system’s template. It was a smooth process.

Implementation was very easy for us. We simply explained the flow chart to our account manager at Optimum, and she took care of everything. She worked with us to use our marine terminology with the system’s template. It was a smooth process.

Key Features of Optimum’s Service Management Software:

-

Digital Checklist: Optimum replicated Bhawani’s inspection checklists within the system. This ensured service engineers had instant access to standardized procedures, improving efficiency and accuracy.

-

Centralized Database: Handwritten records transitioned to a digital database, categorizing davit models and assigning serial numbers. This transformation improved traceability, streamlined record-keeping, and ensured seamless tracking across inspections and servicing.

-

Automated Workflows: A flowchart-based system was implemented for creating work orders, managing checklists, and generating certificates. By automating these tasks, Bhawani reduced manual effort and enhanced service efficiency.

-

Training Certification and Engineer Records: The system enabled Bhawani to issue training certificates to authorized service stations and maintain detailed certification records of their engineers. This has strengthened Bhawani’s ability to ensure compliance and maintain quality across service operations.

It was such a tedious process before, following up with each service center, waiting on feedback, and exchanging documents back and forth. I’m so glad this was resolved with the Service Management system,

It was such a tedious process before, following up with each service center, waiting on feedback, and exchanging documents back and forth. I’m so glad this was resolved with the Service Management system,

Mohit explained.

Results: Gained Efficiency and Acquisition of a Major Contract

After implementing Optimum’s Service Management Software, Bhawani Engineering experienced significant improvements:

-

More Efficient Service Operations: Work order processing became seamless, reducing turnaround times for inspections and certifications. Reports were submitted on time, ensuring compliance with maritime regulations.

-

Elimination of Courier Costs: Previously, documents had to be physically sent between Bhawani and service centers. With the digital system, courier costs for these documents were completely eliminated.

-

Improved Accountability and Security: Improved authentication processes ensured that certificates were accurately linked to the correct davits, preventing misuse. Centralizing certificate management also allowed Bhawani to maintain precise records and restrict access to authorized personnel.

Mohit remarked,

It has been brilliant working with Optimum. The software works like magic for us. I was at first skeptical and didn’t know of the capabilities of the software, but it has turned out to be fantastic. It has solved all my headaches.

It has been brilliant working with Optimum. The software works like magic for us. I was at first skeptical and didn’t know of the capabilities of the software, but it has turned out to be fantastic. It has solved all my headaches.

The Service Management software played a crucial role in helping Bhawani secure a 5-year contract with Adani Shipping, one of the largest shipping companies in India, with a fleet of 180 ships. Adani Shipping recognized that Bhawani’s service management process was organized, had consolidated data, and was efficient in contract management. This was the first Annual Maintenance Contract (AMC) that Adani has ever awarded to a rescue boat davit manufacturer, highlighting the trust and confidence they placed in Bhawani's service management capabilities.

The Future: Expanding Digital Capabilities

Bhawani Engineering plans to expand Optimum’s Service Management Software to further streamline operations. Key enhancements include integrating inventory management to track spare parts usage, automating report generation for regulatory submissions, and incorporating the software into the manufacturing process to manage inquiries, drawing approvals, and final inspections. These improvements will enhance efficiency, compliance, and service consistency.

Reflecting on the broader industry impact, Mohit stated,

I see a huge benefit for other marine equipment manufacturers and service stations if they used Optimum’s Service Management software. Service stations handle a lot of different and complex machinery, not just davits, with different regulations and checklists. With service stations being scattered everywhere, a centralized feedback mechanism would be very helpful.

I see a huge benefit for other marine equipment manufacturers and service stations if they used Optimum’s Service Management software. Service stations handle a lot of different and complex machinery, not just davits, with different regulations and checklists. With service stations being scattered everywhere, a centralized feedback mechanism would be very helpful.